Blowout is a form of uncontrolled formation fluids flow from an oil or gas well which may contain water, gas, oil, or a mix of these fluids. The blowout takes place when pressure control equipment fails to control the pressure of formation fluids. It may lead to the loss of lives, impact health of the crew working on the site, and have adverse effects on the environment. Blowout preventors are being installed on every well to prevent such incidents and avoid loss of lives.

Let us try to understand the cause of blowouts.

Causes of Blowout:

To understand the cause of a blowout, we first need to understand the basic drilling process and the importance of drilling mud which is used while drilling.

Drilling mud is a high density, viscous fluid that is used to bring drill cuttings to the surface. However, it is also used to maintain the borehole's hydrostatic pressure, another key function of drilling mud.

Drilling mud is pumped into the wellbore through the drill pipe to drill bit, where it exits from the nozzles present on the face of the bit to clean the teeth of bits and carry drill cuttings to the surface. While carrying drill cuttings, the mud, which is frequently referred to as Drilling Fluids, helps maintain hydrostatic pressure inside the wellbore. The drilling mud balances the formation fluid pressure, disallowing formation fluids to enter the borehole.

Hydrocarbons are found in subsurface reservoirs, usually in compressed form under high pressure due to the overburden pressure of thick sedimentary layers. The fluid entrained in these formation's pore space exerts pressure on the borehole, which is counterbalanced by high-density drilling mud.

However, sometimes the well encounters an overpressured formation zone while drilling. This overpressured zone exerts extra pressure on the borehole, disabling drilling mud to balance the formation pressure. As a result, the formation fluids start entering the wellbore, a process known as “Kick”.

If a driller detects the kick on time, the chances of blowouts can be reduced by eliminating the kick by pumping high-density drilling mud and by closing the well at its entry point. However, most blowouts take place due to late or non-detection of kicks on time.

In addition to that, a major source for blowouts is the wrong usage of rams to shut the well. Most BOPs come with a rated range, under which a BOP works efficiently. However, wrong pipe rams are ineffective to shut the well completely and served as the main reason for a BOP's failure leading to a major disaster. BOPs are not failing proof equipment if the pressure exceeds further to their specified limit.

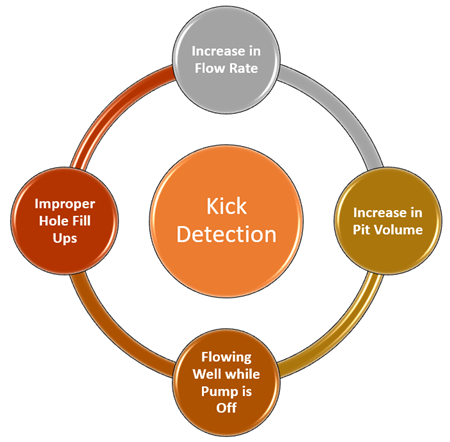

Detection of Kick:

Drillers can detect the kick during the early stage to avoid blowouts. There are various signs of kicks that can be considered and can be considered potential warnings for Kicks. Let us see some of the primary measures to detect the kick into a wellbore.

Copyright © 2021 Kalkine Media Pty Ltd

- Increase in Flow Rate: The increase of flow rate into the annual fluid flow rate is the primary indicator of a potential kick. Ideally, the pumping rate should nearly be equal to the pump-out rate but an increase in the pump-out flow rate means that an extra flow from the formation is aiding the rig pumps by increasing the annular flow rate. This is a very good indicator of potential kick into the wellbore.

- Increase in Pit Volume: A sudden increase in the volume of mud pit due to unprecedented supply of formation fluids can also tell us about the prospects of a coming kick.

- Flowing Well while Pump is Off: This is also a type of direct indicator for the detection of kick. If the rig pumps are stopped but the well is flowing, then this means that the kick has occurred.

- Improper Hole Fill Ups: Ideally, the mud level in a wellbore should decrease when the drill string is pulled out from a well, as mud accommodates the space acquired by the drill string. However, if the well doesn't need any extra amount of mud to bring the level back to the surface, it can be assumed that the kick has occurred.

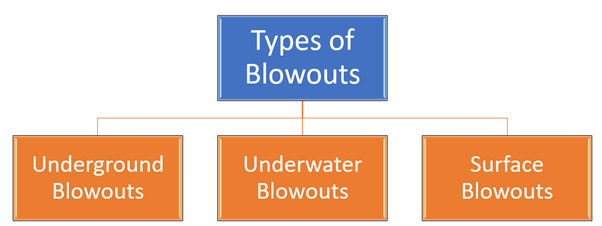

Types of Blowouts:

There are three primary types of blowouts that can be observed while drilling and can lead to disastrous consequences.

Copyright © 2021 Kalkine Media Pty Ltd

- Surface Blowouts: The first and most common type of blowout that is usually observed in the industry is Surface blowout. The fluids enter from the formation and tend to come towards the surface when drilling mud fails to control that pressure. A relief well is used to introduce high-density mud into the wellbore to control the well.

- Underground Blowouts: The uncontrolled flow of formation fluid from a reservoir to a borehole and finally into another reservoir. The crossflow of fluids from one zone to another takes place during underground blowouts. If pressure in the annular space increases, the crew usually closes the BOPs to avoid blowouts.

- Underwater Blowouts: Underwater blowouts are the hardest blowouts to deal with because of their location under the water. Most of the underwater blowouts have been observed during wildcat drilling. However, probability of a huge oil spill is relatively low in this case. Testing conditions of discovery involve greatest risk associated with the exploration. One of the biggest underground blowouts took place in the Gulf of Mexico in 2010 at Deepwater Horizons. The rig was operated by Transocean and leased by British Petroleum in the Macondo oil prospect. The mishap was so serious that it forced the industry to rethink its HSE procedures.

Please wait processing your request...

Please wait processing your request...