What is a Digital Oilfield?

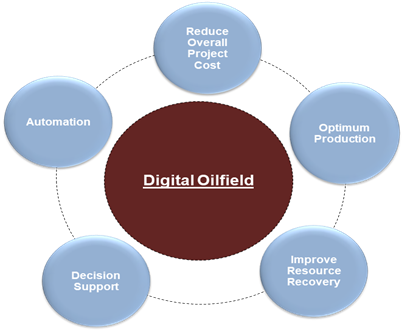

Digital Oilfield, according to the terminology, is not only about sensors and screens installed on an oil and gas field. It is a concept of integration of the business processes with digital technologies and to automate the workflows.

It allows a company to reduce human interference and minimize the risks associated with oil and gas operations. The flow of data and information is rapidly integrated with the analysis interface, allowing timely and best available decisions for the operation.

How are companies leveraging with smart technologies on the oilfield?

Image Source: © Kalkine Group 2020

The upstream oil and gas sector has been a laggard in implementing digital technology. However, the approach towards digitalization has changed in recent years. As a result, a multibillion-dollar industry has emerged to make the oil and gas fields “smart”.

Digital Oilfield integrates multiple data with the analytics tools or applications for knowledge management and decision support system. It allows automating the workflow and helps in remote monitoring of the processes and operations.

The lower crude oil price environment has forced the upstream companies to adapt to the digital oilfield concept to increase efficiency and boost production. Emerging technology trends, including IoT, Big Data, Artificial Intelligence, along with other innovations in technologies, are extensively being used in modern-day oilfields.

The next big question - How do they do it?

Upstream oil sector’s operations can be broadly divided in to:

- Exploration

- Drilling

- Production

- Abandonment

The digital oilfield technology is being implemented mostly to the drilling and production operations. For any oilfield, production is a continuous and closely monitored operation as it generates the revenue. No one wants to lose any of their production.

The technology enables the company to monitor the production data with advance analytics closely, and decision-making system can predict the possible next work-over jobs on the oil wells. The sensors on the well control unit can monitor the hazardous gas leaks, water production or field tank levels.

The cloud computing system, through its storage and immense data processing capabilities, offers smart intelligence and production planning of oil wells. During the lifecycle of a well, its pressure drops due to depletion in oil and gas volumes in the reservoir. The installed smart technology could help in better planning of any possible production cuts in future.

The next major application of the data-driven approach is in drilling. Since the era of easy oil has gone, companies are entering into deeper zones, both on land and sea. Drilling in deep offshore is an extensive capital endeavor which involves a very high risk of human life and environmental losses.

The Deepwater Horizon Gulf of Mexico accident took place during the drilling operations. The well flowed continuously for many days leaking thousands of barrels of oil in the sea. The oil spillage cost BP nearly $20 billion as penalties, and 11 people lost their lives in the accident.

Since the nature of the job and risks presents at the oilfield has made companies realized that the lesser the number of people on-site, lesser would be the causalities. The real-time data monitoring application has helped in reducing the workforce from the site.

Companies, in most of the cases, outsource the real-time data monitoring work to specialized firms who have competence in smart tools and applications. They monitor the data coming from the drill site and keep a watch on the well trajectory, mud pressure, and various other parameters, to govern safe and accurate drilling of the well.

There was a reservation for using the smart well technology or Digital Oilfield among the oil companies as they did not want to increase their operational cost by installing sensors and data analytics centre. But technology has taken a huge leap and provided solutions that were not available before.

For instance, digital technology can provide simulations for various case scenarios related to the production or reservoir behaviour pattern. The operator, or the decision-making body, can take a call based on the most optimum solution. This has helped cut down the overall project costs.

In a nutshell, digital oilfield is a concept to integrate technologies like artificial intelligence, cloud computing and data analytics. The processed information is then channelized towards the intended receivers.

Please wait processing your request...

Please wait processing your request...