Define Downstream:

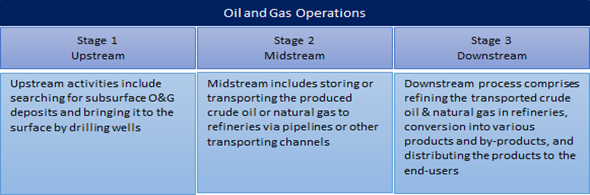

Downstream is the third and the last stage of the comprehensive oil and gas (O&G) process, with the first two being Upstream, and Midstream. Downstream is an essential process in the petroleum industry that is responsible for refining, distribution, and retails of petroleum products. All the methods which are involved in turning natural gas & oil to user-centric petroleum products come under Downstream processes.

Image Source © Kalkine Group

Downstream Process:

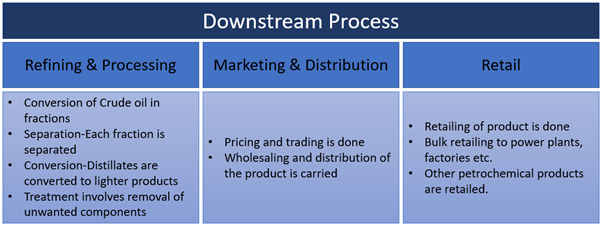

This segment of the O&G industry refers to any process that is required to refine, process, purify the raw crude oil or gas into a user-centric product. The downstream sector is responsible for the supply of thousands of petroleum products used by consumers worldwide. Most of the familiar petrochemical products which we use in our day-to-day life are gasoline, diesel, asphalt, plastic, rubber, fertilizers, pesticides etc. The main components of the Downstream process are Refining & Processing, Marketing & Distribution and Retail.

Image Source © Kalkine Group

Refining & Processing

Crude oil is made up of a large number of hydrocarbon molecules. The lighter molecules of gas contain Carbon atoms ranging from 1-4, whereas higher hydrocarbons might consist of 20 Carbon atoms as well. The molecules are present in varying proportion depending on the source and maturity of the organic matter. Consumers can't use crude oil directly into vehicles or machines. It needs to be refined & processed before using. Refining involved three necessary steps that are Separation, Conversion and Treatment.

In Separation, the liquid and vapours are separated into petroleum components according to the boiling point of the dissolved components known as Fractions. The lightest fractions include gasoline and liquified refinery gases; medium weight liquids include kerosene and distillates whereas heavier liquids consist of gas oils which are collected at the bottom of the distillation tower.

In Conversion, distillates and heavy liquids are processed and converted into lighter products using Catalytic Cracking. High pressure, heat and catalyst are the main components used in the cracking process. 75% of the heavy products are converted into gas, gasoline, and diesel by this process.

The last step of Treatment involves the removal of undesired components from the product, which can harm the transportation process like removal of Sulfur which is highly corrosive. Thiols are removed from Butane & Kerosene by washing & this process is known as Sweetening.

Marketing & Distribution

After the refining & processing of crude oil is complete, the next step is to market & distribute the products in the international market. The pricing and demand for the petroleum products may vary depending on numerous reasons like distance of transportation, political conditions and economics. Marketing involves the wholesaling and distribution of the product. Transport can be done via different types of mediums like oil tankers through roads/railways or through tanker ships. Many midstream companies play a vital role in the transportation of petroleum products to the end-users.

Retail

This is the final step in the downstream process, i.e. retailing of the end-products. A large amount of retailing is done to factories, power plants and in the transport industry where a small section of retail consists of supply to pumping stations. There are thousands of more products which are made available for the end-users like lubricants, rubber, plastic, fertilizers, pesticides, and other petrochemical products.

Please wait processing your request...

Please wait processing your request...