An oil rig is a megastructure used to drill a well to explore and extract hydrocarbons from the subsurface formations to surface. Oil rigs also contain primary storage and processing facilities for the explored hydrocarbon. There are numerous kinds of oil rigs available, depending on the location and depth of well to drill.

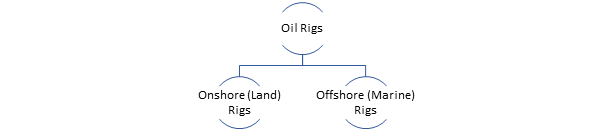

What are the types of Oil Rig?

Broadly, based on the location of a well to be drilled, oil rigs can be classified into two major types. Onshore rigs are used to drill a well in the onshore region, whereas the rigs used to drill wells in the offshore area are known as Offshore rigs.

Onshore Drilling Rigs:

Onshore drilling rigs are used to drill wells on land. The main feature of land rigs is mobility and depth of penetration. Most of the components used to fabricate the structure are present in the form of modules and are skid-mounted to be assembled and reused easily.

How are Rigs Classified?

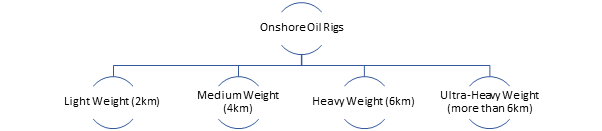

- Classification based on Depth of Penetration:

Land-based rigs can be further classified into four major types based on the ultimate depth of penetration of well. Although, they look similar to each other but vary in the technical specification.

4 Broad categories are:

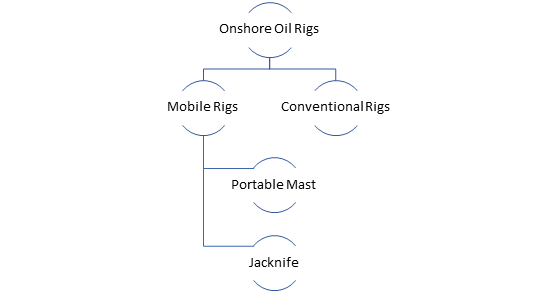

- Classification based on mobility:

Onshore rigs can further be classified based on the mobility of rig. This signifies the ease of portability of a rig when the task at one location is completed, and there is a need to transport the rig at a new location.

- Conventional rigs are giant structures, and they can't be mobilized as a single entity from one place to another. Mostly, parts of the rig are skid mounted so that they can be transported and assembled easily. These types of Rigs are commonly used for land operational drilling in the oil industry.

- Mobile rigs are compressed form of drilling rigs which are mounted on trucks. In Jacknife type of rig, the derrick is assembled and raised on the ground using different power sources. Prefabricated units can be transported using trucks, ships or helicopters depending on the accessibility.

- Portable Mast rigs are suitable for moderate depths of drilling. It is mounted on trucks and mast is raised using a hydraulic piston system.

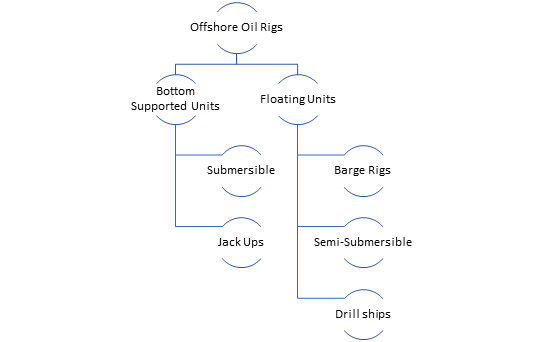

Offshore Drilling Rigs:

The exploration for hydrocarbon in oceans started in the early 20th century, which forced engineers to transform the land-based rigs that can suitably be used in marine settings. This gave birth to offshore rigs. Offshore drilling rigs are used to drill wells on marine location. The main feature of marine rigs is movability and sea-bed depth. Most of the components used to fabricate the structure are present in the form of modules and are skid-mounted so that they can easily be transported, assembled, and reused. Mainly offshore rigs are classified into two major types:

- Bottom Supported Units:

Bottom supported units are used for relatively shallower seafloor depth. The part of their structure remains in contact with the sea-bed. The remaining part of the rig is designed in such a way that it can float into water reducing the sheer weight in the contacted part. The rig can float if required during the time of transportation. These are basically of two main types: Submersible and Jack-ups.

- Submersible Rigs: These rigs are like a flat-bottomed boat which take into consideration water ballasting and de-ballasting to position, anchor and re-glide the gigantic structure. All-important drilling system is fitted on the platform, like the drilling barges & jack-ups. Their tasks are designed to operate in shallow waters because of their submersible design.

- Jack-Ups: These rigs are placed onto the site by bringing down and establishing its three or four giant legs on the ocean bottom. The barges are then lifted up above the water. They are more stable than the floating rigs and are suitable for drilling starting from 100 meters of depth and can drill up to 9.1 km of depth.

- Floating Units:

Floating units, as the name suggests, are the megastructure which doesn't rest on the ocean floor; instead, they float on the ocean water. Anchors are present to stabilize the rig remains in contact with the seafloor. These units include Drillships, Semi-Submersible, and Barge rigs.

- Barge Rigs:Barge rigs are used for shallow-water drilling in calm water conditions. Drilling system is put on to the deck of the barge and towed to the site by pulls. Anchors are used to stabilizing the rig in a designated position.

- Drill Ships: Drill ships, typically designed on big hulls, have been fitted with drilling machinery and are utilized in the ultra-deep operation of up to 3000m. Dynamic positioning system keeps the rig positioned accurately over the well.

- Semi-Submersible Rigs: A Semi-Submersible rig is a Mobile Offshore Drilling Unit which is commonly known as MODU. This rig is intended to drill in ultra-deep conditions where the depth of the ocean floor is more. It is extensively used to drill deeper reservoirs of oil & gas present all over the world. These are partially submerged in water during the drilling operation and are moored to the seafloor by the anchors.

Please wait processing your request...

Please wait processing your request...