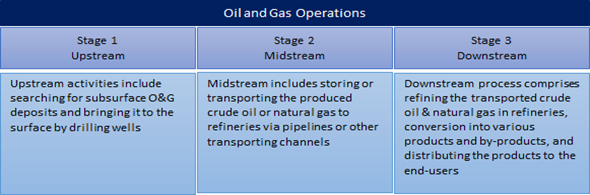

The complete O&G process consists of various steps, ranging from searching for subsurface deposits of petroleum, extraction, transportation of extracted material to refineries, and then finally refining it & making it available for customers. Midstream is one three crucial stages involved in the O&G processes.

In the oil & gas sector, all the activities which are related to storage, processing, and transportation of oil and natural gas, are termed as Midstream activities. The complete O&G process consists of three main categories -- Upstream, Midstream and Downstream:

Image Source © Kalkine Group

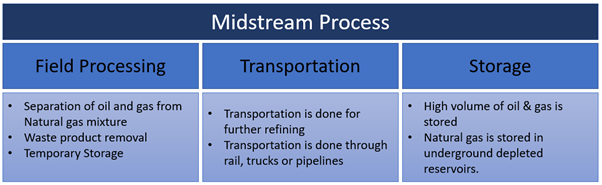

Midstream Process:

Midstream process in the O&G industry refers to actions required to store and transport the extracted crude oil or natural gas from the subsurface reservoir to refining. Raw crude oil and gas need to be processed before transportation to extract valuable NGL (Natural Gas Liquids) from it. Midstream includes transportation of the processed crude oil and natural gas from the place of origin to refineries like pumping stations, rail & truck tankers, pipelines etc. The midstream process consists of three main parts:

Image Source © Kalkine Group

Field Processing:

The raw crude comes in a mixture form of oil, natural gas, and natural gas liquids which are flown into different types of separators. Separators can be Horizontal, Vertical or Spherical, depending on the operation, either offshore or onshore. The separator separates water and oil from the mixture. After this removal of impurities is carried out, followed by Fractionation, where Natural Gas Liquids (NGL) are extracted from produced raw crude or natural gas. These NGL's are used as a blend component in refineries and feedstock for the manufacturing of other petrochemical products.

The separated water is again pumped into the disposal well, while O&G is fed into temporary storage units.

Transportation:

Transportation is a significant segment of the midstream process since crude oil and gas must be moved to refineries for additional refining and ensuring its availability to the consumers. The primary types of transportation of crude oil and gas incorporate pipeline, truck, rail, and tanker ships.

Crude oil, gas, and natural gas liquids are shipped from the well, where they are explored, to an offsite temporary storage facility and moved to a gathering facility for refining. Whenever they are refined, the end petroleum products, for example, gasoline, LPG, diesel, and stream fuel, are made available for end-users, for example, homes, production lines, and gas stations.

Pipelines are the most well-known methods for transporting crude oil and gas over significant distances since they are a relatively more secure-and-efficient medium of transportation. Tanker mounted trucks are used to move oil and gas from the place of origin to treatment facilities or from processing plants to the end-users. Despite the fact that trucks move the lowest volume of oil-based commodities, they make up for the inflexibility of different methods for oil transportation, for example, pipelines and ships. On the other hand, railways are considered as the cheapest mode of transportation.

Storage:

Storage facility plays a vital role in regulating the demand and supply in the market. Storage facilities include bulk terminals, refinery tanks and holding tanks to send material into pipelines, or ready to be shipped on a vessel. The large volume of hydrocarbons is stored in the storage tanks.

Storage levels matter all around the world since they affect oil prices. Storage has additional significance since it ensures energy security in case of any critical situation, like COVID 19, arises and interrupts the supply.

As per the International Energy Program Agreement (I.E.P. Agreement) of 1974, International Energy Agency (IEA) members are required to hold oil stocks equivalent to at least 90 days of net oil imports.

Because of the high pressure of Natural gas, it is stored in depleted underground reservoirs, like salt caverns and aquifers, until it gets ready to transport to market. Nowadays, due to advancement in technology and limitations, naturally-occurring reservoirs LNG came into existence where the gas can be liquefied and stored in LNG tankers.

Please wait processing your request...

Please wait processing your request...